T-shirts have become more than just a wardrobe staple; they are now a canvas for self-expression and creativity. The world of t-shirt printing has evolved significantly over the years, offering a plethora of techniques that can transform a simple shirt into a work of art.

Whether you’re a fashion enthusiast, an entrepreneur venturing into the apparel industry, or simply someone who loves unique and eye-catching designs, understanding the different types of t-shirt printing is key to unleashing your artistic potential.

In this comprehensive guide, we’ll take you on an exciting journey through the 10 different types of t-shirt printing, each with its own distinctive charm and appeal. With a blend of timeless traditions and cutting-edge innovations, these techniques embrace diverse preferences and design dreams.

Table of Contents

Most Common Types of T-Shirt Printing

We will delve deeper into the ten best t-shirt printing methods within this dedicated segment, meticulously examining their attributes, advantages, and potential drawbacks. By understanding each method’s unique merits and limitations, you can make well-informed decisions, ensuring your t-shirt printing endeavors yield the best possible results tailored to your specific needs and creative aspirations.

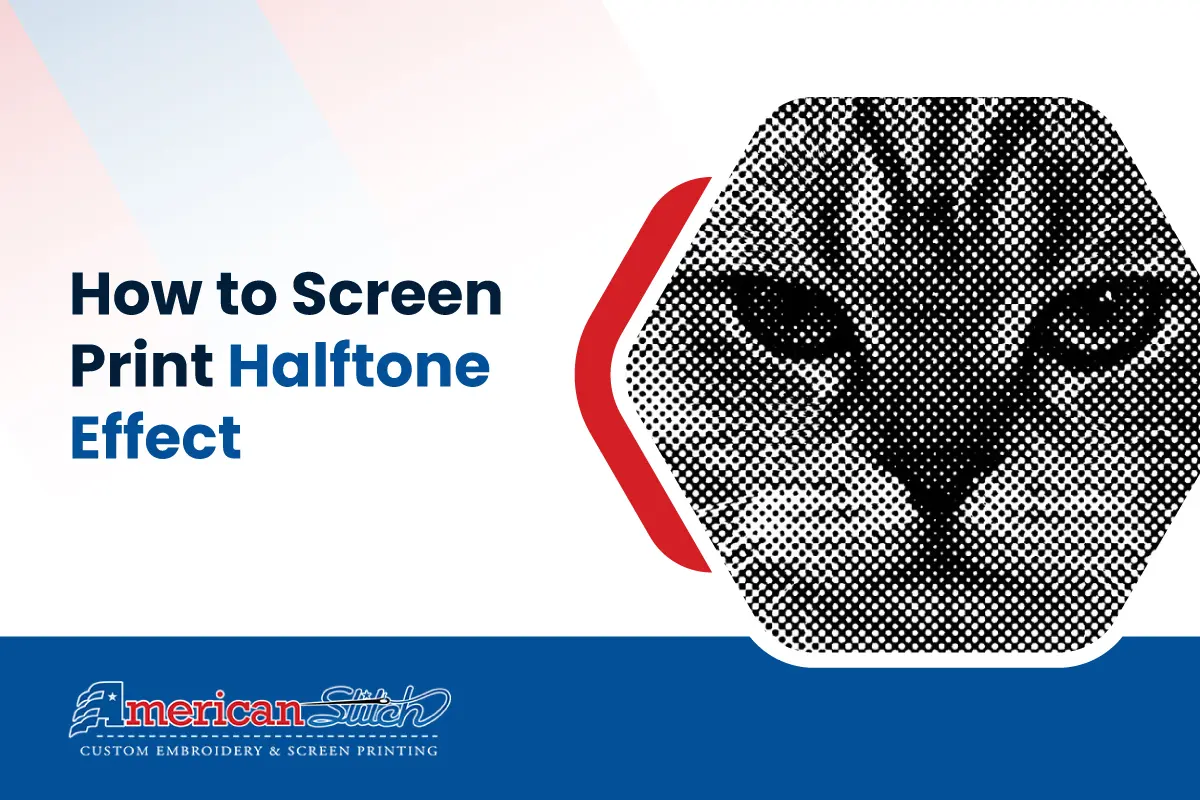

Screen Printing

Screen printing is a renowned and time-honored t-shirt printing method of transferring designs onto various surfaces.

Often referred to as silk-screen printing, this technique utilizes a fine mesh screen to expertly apply ink onto the material, giving birth to mesmerizing and vivid prints. This artistic technique has been cherished for centuries and remains a popular choice in the world of apparel and promotional products.

Screen printing’s popularity lies in its wide range of color choices, making designs vibrant and appealing. Plus, it works well on darker fabrics too, ensuring captivating prints that stand out.

Pros of Screen Printing:

- Exceptional durability

- Vibrant and colorful prints

- Speedy printing process for mass production of t-shirts

- Cost-effective for bulk orders

- Suitable for various materials

- Versatility in printing surfaces.

Cons of Screen Printing:

- Setting up the screens for screen printing can be time-consuming

- less practical for small-scale or one-off projects

- Limited details in prints

- Not suitable for complex designs.

Direct to Garment (DTG) Printing

Direct to Fabric (DTF) printing, a pioneering technique in the custom apparel industry, represents a technological leap that has transformed how personalized garments are produced.

It involves using specialized inkjet printers to directly apply ink onto garments, allowing for high-quality and detailed designs without needing screens or stencils. It’s a type of t-shirt printing you feel like paper printing.

As a relatively new printing technology, DTG has quickly gained popularity for its versatility and precision in producing personalized and eye-catching apparel. Given its digital nature, this process yields sharper prints with a higher resolution or DPI compared to conventional printing techniques like screen printing.

Pros of Direct to Garment (DTG) Printing:

- Rapid turnaround time in comparison to screen printing

- Cost-effective choice for low volume runs

- Ideal for designs requiring multiple colors

- DTG printing typically uses water-based inks, which are eco-friendly

- Eliminates the need for artwork to be separated by layers or in vector format

Cons of Direct to Garment (DTG) Printing:

- Dark and colored garments require a ‘pre-treatment’ or ‘underbase layer’

- Heat pressing and tunnel heating are essential steps

- Pre-treatment may occasionally cause noticeable staining on the fabric

- Prints on dark and colored garments may appear less vibrant or grainy

- Exact Pantone (PMS) color matching is not possible with DTG

- For DTG printing, choose garments with at least 80% cotton content; low-cotton polyester or sportswear may not be suitable.

Heat Transfer Printing

Known as thermal printing, heat transfer printing stands as a versatile and beloved technique for imprinting designs onto an array of surfaces, encompassing garments, bags, and promotional items.

This ingenious method revolves around the transfer of designs from specialized paper, named transfer paper, onto fabric or materials through the application of heat and pressure. Heat transfer printing offers a wide range of applications and can produce vibrant and detailed prints, making it a preferred choice for both small-scale and large-scale production.

Its convenience, capability to generate vibrant full-color prints and cost-effectiveness for smaller quantities render it a precious choice for individuals and businesses aiming to infuse their products with a personalized touch.

Pros of Heat Transfer Printing:

- Versatility in Design

- Ease of Use

- Ideal for Small Batches

- Quick Turnaround Time

- Environmentally friendly.

Cons of Heat Transfer Printing:

- Doesn’t last as long as traditional screen printing

- Has a rubbery feel due to the printer ink coverage on the design

- Can’t iron the printed t-shirt because the heat ruins the image

- Unsuitable for printing many units because large quantity runs are time-consuming and expensive

- Not ideal for dark fabrics.

Sublimation Printing

If you’re new to the printing world, there are different types of t-shirt printing available. But among them, sublimation printing is the most eye-catching t-shirt printing method.

It is a fascinating dye-sublimation t-shirt printing method that has become a sought-after method for transferring designs onto various materials, particularly polyester fabrics. Unlike traditional printing, sublimation uses heat to turn ink into a gas, infusing it into the fabric’s fibers, resulting in vibrant, long-lasting, and fade-resistant prints.

Imagine sublimation printing as akin to tattooing, except instead of skin; fabric becomes the canvas. This innovative process has gained immense popularity in the world of custom apparel, home decor, and promotional products.

Pros of Sublimation Printing:

- Allow printing on rigid surfaces (mugs, photo slates, plates, clocks, etc.)

- Relatively simple and has a very short learning curve

- Offers an unlimited range of colors

- There is no additional cost when adding a new color to your design

- The unit cost remains the same whether you personalize 1 or 1000 units

- Unlike transfer paper, the result is seamless, scratch-resistant, and colorfast

- Can produce orders on the same day.

Cons of Sublimation Printing:

- Limited to items with a special polyester coating for non-textile substrates

- Not suitable for black or dark-colored surface

- Potential color fading over time due to UV ray exposure

- The initial investment can be higher compared to other printing methods

- Printing size is restricted, as with other digital image transfer methods.

Vinyl Cutting

Vinyl cutting, or vinyl plotter cutting, is a precise and versatile t-shirt printing method used to create designs by cutting vinyl sheets into intricate shapes and patterns. This process involves using a vinyl cutter or plotter equipped with a sharp blade that cuts through the vinyl material.

The design is created digitally, and the vinyl cutter follows the path, cutting the vinyl sheet accordingly. This technique is widely used for creating custom stickers, decals, lettering, and other personalized designs on various surfaces.

Pros of Vinyl Cutting:

- Vinyl cutting offers remarkable precision, allowing for intricate and detailed designs

- This technique can be applied to several fabric types

- Suitable for both indoor and outdoor applications

- This process allows for a low setup cost

- It can easily apply to various surfaces, including walls, windows, vehicles, and apparel.

Cons of Vinyl Cutting:

- Unlike other printing methods, vinyl cutting has limitations in color blending.

- Not Ideal for Full-Color Photographic Prints

- Vinyl cutters have size limitations

- Producing a large quantity of vinyl cut designs can be labor-intensive

- Large designs add unnecessary weight to the garment.

Embroidery

Embroidery is an exquisite and timeless art form that uses needle and thread to decorate fabric with intricate designs, patterns, and motifs. Embroidery presents an extensive spectrum of thread or yarn hues, offering a personalized touch to gifts and clothing articles.

This technique has been cherished for centuries and remains a favored choice for adding elegance, texture, and a touch of sophistication to various items, including garments, accessories, home decor, and corporate branding.

Pros of Embroidery:

- Extremely long-lasting

- Retains its color very well

- Offers unmatched elegance and fine detailing

- Embroidery excels on challenging materials like fleece and heavy cotton

- Embroidery is an excellent choice for corporate branding

- Enables up to 20 colors in one design at no extra cost.

Cons of Embroidery:

- Embroidery is typically more expensive than printing

- Not all designs are suited to embroidery

- Not ideal for thin or delicate fabrics

- Embroidery demands meticulous skill and considerable time investment

- Design changes during embroidery are challenging and costly once the process begins.

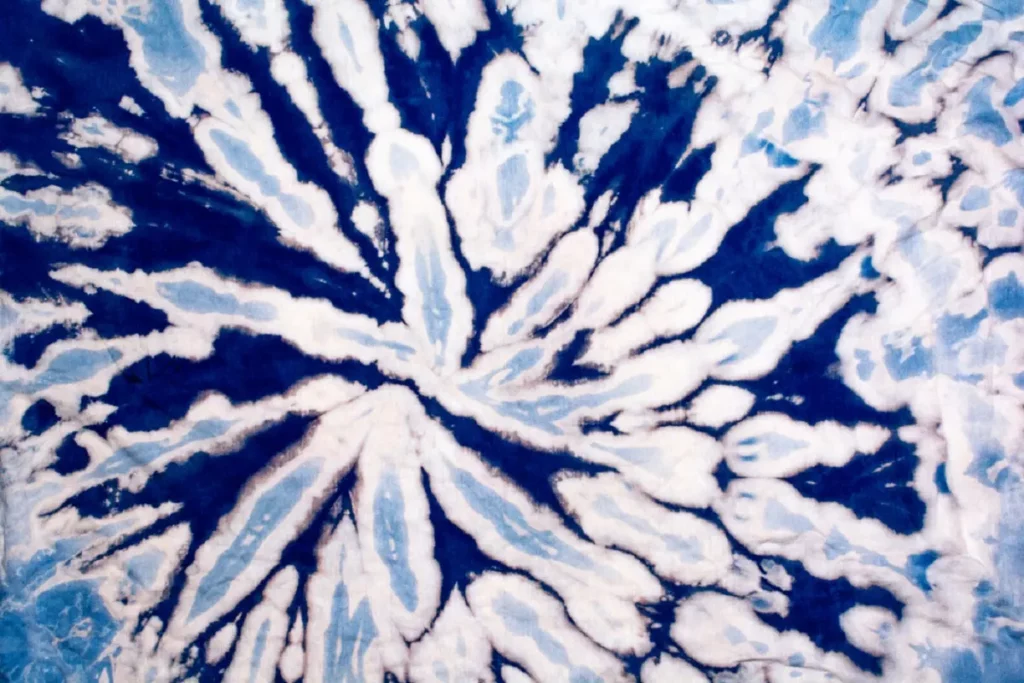

Bleach Printing

Bleach printing is a creative and innovative technique that involves transforming the color of fabric through controlled oxidation. Unlike traditional printing methods, bleach printing removes color from the fabric rather than adding ink or pigment. This captivating process allows artists and designers to craft unique and expressive designs on garments and textiles.

Pros of Bleach Printing:

- Bleach printing offers endless possibilities for creativity

- It is an affordable and easily accessible material

- Bleach printing adds texture by altering fabric color and surface

- Bleach printing is eco-friendlier than traditional methods, using fewer materials.

Cons of Bleach Printing:

- Bleach printing can yield unpredictable outcomes

- Limited color range and intricate blends may not be achievable

- Not all fabrics react well to bleach printing

- Protective gear is necessary to ensure safe handling

- Bleached areas may weaken over time, affecting garment longevity.

Foil Printing

Foil printing stands as a specialized print technique, harnessing heat, pressure, and metallic paper. It’s a captivating embellishment t-shirt printing method, adding an air of opulence to diverse surfaces. Through this process, metallic or pigmented foil is meticulously applied, yielding designs that shimmer under light and create mesmerizing visual effects.

Notably, foil printing boasts an extensive array of colors and finishes. While gold and silver foils remain iconic choices, an array of other hues and effects, like holographic and iridescent, expand the possibilities, mimicking the allure of precious metals.

This dynamic range of options is what sets foil printing apart, enabling artists and designers to craft distinctive and dazzling creations that captivate the senses.

Pros of Foil Printing:

- Foil printing instantly imparts a luxurious and premium look to designs

- Foil offers a spectrum of colors, from traditional gold and silver to vibrant hues, allowing for diverse palettes and unique effects

- Allows intricate patterns, bold typography, and detailed graphics

- Foil printing is highly durable and resistant to fading.

Cons of Foil Printing:

- Foil printing can be more expensive compared to other embellishment methods

- may not be suitable for designs with intricate details

- may not work as effectively on textured or uneven substrates

- Not all designs may be suitable for foil printing

- Foil printing may not appear as vibrant on dark backgrounds.

Water-Based Printing

Among all the types of t-shirt printing, water-based printing is a sustainable and environmentally conscious technique that leverages water as the foundation for ink, eschewing the conventional use of petroleum-based solvents.

Distinguished by its water-based ink, this method applies a fine, supple layer of ink onto the garment. This produces a delicate ink deposit that upholds its integrity through numerous wash cycles. Upon completion, cleanup is effortlessly managed with water or equivalent cleaning agents.

This ingenuity brings forth an assortment of advantages while prioritizing ecological considerations. It has emerged as a conscientious preference for fashioning dynamic and premium designs across a spectrum of textiles and substances, underpinning a commitment to quality and the environment.

Pros of Water-Based Printing:

- Water-based inks are non-toxic and free from harmful chemicals

- Offers a soft, breathable texture, preserving fabric’s natural feel

- Water-based inks permeate fabric, yielding enduring, vivid prints post-washes

- Suitable for light and dark fabrics, offering design versatility

- Pairs exceptionally well with organic and eco-friendly textiles.

Cons of Water-Based Printing:

- Have limitations in achieving intense color opacity on dark fabrics

- Require an extended drying time compared to traditional t-shirt printing methods

- Achieving optimal results with water-based printing may require a learning curve

- Water-based printing may not adhere well to synthetic fabrics

- The equipment required for this printing technique can be more expensive upfront.

Discharge Printing

Discharge printing emerges as a captivating and inventive method, weaving its uniqueness through the fabric of textile design. It delves into the art of subtraction, where color is removed from a dyed fabric to unveil intricate and meticulously detailed designs.

In the delicate choreography of discharge printing, the discharge agent performs its symphony of molecular breakdown, unraveling the original color and allowing new patterns to emerge. As the fabric embraces this transformation, the designs take on an air of mystique, resonating with a balance of vividness and subtlety.

Beyond the visual symphony it orchestrates, discharge printing also echoes sustainability. By effacing existing dyes rather than adding new pigments, it resonates with a more eco-conscious cadence, capturing the essence of responsible creativity.

Pros of Discharge Printing:

- Discharge printing results in remarkably soft designs for maximum apparel comfort

- Vibrant and intricate designs emerge, captivating even on dark fabrics

- Discharge printing is environmentally friendly

- Never have to worry about the design cracking

- Ensuring longevity even after repeated washes

- Discharge printing can be used on various fabric types.

Cons of Discharge Printing:

- Complex designs may require adjustments

- It is an expensive process

- The discharge agent can have a distinct odor during the printing process

- Limited to natural fibers such as cotton; unsuitable for 50/50 blends.

- Not all fabrics react well to discharge agents

- Expertise is essential for achieving consistent and desired discharge printing outcomes.

What Types of T-Shirt Printing Methods Should You Choose?

When selecting the perfect t-shirt printing method, several factors come into play. From design quality to durability, each types of t-shirt printing offers unique attributes that cater to different preferences and requirements.

Let’s delve into a comparison of these methods to help you make an informed choice:

| Method | Quality | Print Area | Design Options | Durability | Time | Volume | Cost |

|---|---|---|---|---|---|---|---|

| Screen Printing | High | Versatile | Detailed | Durable | Longer | High | Moderate |

| DTG Printing | High | Detailed | Full-color | Moderate | Quick | Low | Moderate |

| Vinyl Cutting | Good | Limited | Limited Colors | Durable | Quick | Low | Low |

| Embroidery | High | Limited | Texture/Depth | Durable | Longer | Low | High |

| Foil Printing | Luxurious | Limited | Metallic Shine | Durable | Longer | Low | Moderate |

| Water-Based Printing | Soft | Detailed | Vibrant Colors | Durable | Quick | Moderate | Moderate |

| Discharge Printing | Intricate | Detailed | Limited Colors | Durable | Quick | Low | Moderate |

| Sublimation Printing | Vibrant | Full Coverage | Full-color | Moderate | Quick | High | Moderate |

| Heat Transfer Printing | Good | Versatile | Multicolor | Moderate | Quick | Moderate | Low |

| Bleach Printing | Unique | Detailed | Multicolor | Moderate | Quick | Moderate | Low |

Each t-shirt printing method brings its own charm and benefits to the table. The choice ultimately depends on your design, preferences, budget, and desired outcome. Whether you’re aiming for intricate details, vibrant colors, or a touch of luxury, there’s a technique that aligns perfectly with your vision.

Personalize Your Tees with Screen Printing and Embroidery by American Stitch in Las Vegas

Elevate your style and make a statement that’s uniquely yours with American Stitch’s exceptional screen printing and embroidery printing right here in Las Vegas. Our team is dedicated to turning your ordinary tees into wearable works of art, capturing your personality and creativity in every stitch and print.

Whether you want to showcase a bold design, a favorite quote, or a team logo, our screen printing expertise ensures vibrant and intricate details that pop. And if you want to add texture and dimension, our embroidery services can bring your vision to life with impeccable craftsmanship.

Contact us today to explore the endless possibilities, or visit our service page to learn more about how you can personalize your tees with our top-notch screen printing and embroidery techniques. Unleash your creativity and let your tees do the talking with American Stitch!