Screen printing, also known as silk-screen printing or serigraphy, is a popular and versatile printing method that has found its place in a wide range of industries worldwide. This process involves pressing ink through a mesh screen to create a printed design on various surfaces, including clothing, canvases, artwork, posters, and more. In this comprehensive guide, we will delve into the intricacies of screen printing, from its basic principles to its various applications and advantages over other printing techniques.

Table of Contents

What is Screen Printing?

Screen printing is an ingenious method of transferring a stenciled design onto a flat surface using a mesh screen, ink, and a squeegee. While fabric and paper are the most commonly screen-printed surfaces, the versatility of this technique extends to wood, metal, plastic, and even glass with the use of specialized inks. The fundamental process involves creating a stencil on a fine mesh screen and then applying ink (or paint, for artistic endeavors) to produce an imprint of your design on the underlying surface.

The method can be referred to as ‘silk screening’ or ‘silk screen printing,’ and though the printing process remains consistent, the stencil’s creation method may vary based on materials. Various stenciling techniques include:

- Using masking tape or vinyl to mask off desired areas of the screen.

- Painting the stencil directly onto the mesh screen using ‘screen blockers’ like glue or lacquer.

- Employing a light-sensitive emulsion to create a stencil, subsequently developed similarly to a photograph.

Designs crafted using screen printing can feature a single ink shade or multiple hues, with multicolored items requiring individual layers and separate stencils for each ink.

Why is Screen Printing So Popular?

The popularity of screen printing can be attributed to several factors, with one of the most compelling being the extensive color options it offers. Notably, screen printing is effective on darker fabrics, allowing for vibrant and durable prints. Moreover, this method enables rapid reproduction of designs, making it an ideal choice for bulk production of garments and accessories.

Compared to digital printing, professional screen printing companies can achieve more vivid and intense colors. However, it’s essential to keep in mind that screen printing has its limitations when it comes to the number of colors that can be used in a single design.

The Screen Printing Process: Step by Step

While various screen printing methods exist, they all adhere to the same fundamental technique. In the following sections, we will explore the screen printing process step by step:

Step 1: Design Creation

The process commences with the creation of the desired design, printed onto a transparent acetate film, which serves as the stencil template.

Step 2: Screen Preparation

A mesh screen, chosen to match the design’s complexity and fabric texture, is coated with light-reactive emulsion, which hardens when exposed to bright light.

Step 3: Emulsion Exposure

The acetate sheet, bearing the design, is placed onto the emulsion-coated screen and exposed to intense light. This light-hardens the emulsion, leaving the design areas unhardened.

Step 4: Stencil Development

After the required exposure time, the unhardened emulsion is rinsed away, leaving a clear imprint of the design on the screen for ink application. The screen is then dried, and any necessary touch-ups are made to ensure accuracy.

Step 5: Item Preparation

The screen is positioned on the printing press, with the item to be printed placed underneath it. Various types of presses, including manual and automatic, can be used, allowing for efficient multicolored prints.

Step 6: Ink Application

The screen is lowered onto the printing board, and ink is applied to the top of the screen. A squeegee is used to draw the ink across the screen, pressing it through the stencil and onto the item underneath. For multiple items, the screen is raised, and the process is repeated.

Step 7: Drying and Inspection

The printed product is sent through a dryer to cure the ink and achieve a durable finish. After thorough inspection and washing to remove any residue, the final product is ready for distribution.

A Guide to Screen Printing Equipment

To achieve precise, high-quality prints, a screen printer requires the right equipment. Let’s delve into the essential components of screen printing equipment:

Screen Printing Press

While it’s possible to screen print with just a mesh screen and a squeegee, most printers opt for a press, as it streamlines the printing process. Manual, semi-automatic, and automatic presses are available. Manual presses require manual operation, semi-automatic presses combine mechanization with manual input, and automatic presses are fully automated, ideal for large-scale production. The choice depends on the printing volume and efficiency needed.

The Inks

Inks, pigments, or paint are crucial for transferring the design onto the item. There’s more to ink selection than color; specialty inks can create various effects, such as glitter, texture, or raised surfaces. Additionally, ink choice considers the fabric type, ensuring washability for clothing items.

The Silk Screen

The silk screen, traditionally crafted from silk thread (now commonly polyester), features a metal or wooden frame with a fine mesh fabric. The mesh thickness and thread count are tailored to match the printing surface’s texture and detail requirements. Once coated in emulsion and exposed, the screen serves as the stencil, washable and reusable after each print run.

The Squeegee

A squeegee, with a rubber blade attached to a handle, is used to push ink through the mesh screen and onto the surface. Blade firmness selection depends on the design intricacy, ensuring even ink coverage. A firmer blade suits detailed designs, while a softer one is ideal for less detailed prints or fabric.

The Washing Station

Screens must be thoroughly washed to remove emulsion remnants, preparing them for reuse. Cleaning methods vary, with options ranging from specialized cleaning fluids to water troughs and power hoses.

Will Screen Printing Ink Wash Out?

When professionally executed using the correct washable heat-treated ink and precise process parameters, screen printing ink should not wash out. Properly dried and heat-treated, screen printing results in long-lasting, color-fast products that maintain their vibrancy even after multiple washes.

History of Screen Printing

Screen printing has a long history dating back over a thousand years. The earliest examples of screen printing were found in China during the Song Dynasty (960-1279 AD), where stencils were used to print decorative designs onto fabrics.

Screen printing was also practiced in Japan, where it was known as katazome, and in India, where it was used to print intricate designs onto textiles.

In the 18th century, screen printing was introduced to the Western world, where it was used primarily for printing wallpaper and other decorative purposes. In the early 1900s, screen printing began to be used for commercial applications, particularly in the textile industry.

During World War II, screen printing was used extensively for printing flags, banners, and other military materials. After the war, screen printing continued to be used in the textile industry, and new applications emerged in the form of printed circuit boards and other industrial products.

In the 1960s and 1970s, screen printing became popular in the United States as a medium for creating art prints and posters, particularly in the counterculture movement.

Today, screen printing continues to be a popular printing method for textiles, signage, and industrial products. The process has been refined with new technologies and materials, allowing for more precise and efficient printing.

How Does Screen Printing Work?

At its core, screen printing is about creating a stencil on a mesh screen and then using this stencil to apply ink to the chosen material’s surface. While the fundamental process remains consistent, there are various techniques for creating the stencil itself. One of the key advantages of screen printing is its ability to use multiple shades of ink in the design. However, for multi-colored designs, each color typically requires a separate stencil.

Origins of Screen Printing

The origins of screen printing can be traced back over a thousand years to various cultures across the globe, including China, Japan, and India.

In China, screen printing was used during the Song Dynasty (960-1279 AD) to print decorative designs onto fabrics. Stencils made of silk were used to create the designs, and the ink was applied using a brush.

In Japan, screen printing was known as katazome and was used to print designs onto fabrics for clothing and other textiles. The process involved creating stencils using paper and glue, which were then applied to the fabric with a brush or spatula.

In India, screen printing was used to print intricate designs onto textiles using stencils made of woven silk or cotton. The designs were created by blocking out certain areas of the stencil with wax or clay, which prevented the ink from passing through.

The early forms of screen printing were labor-intensive and required a high degree of skill and precision. However, they paved the way for the development of modern screen printing techniques, which are now used in a wide range of industries and applications.

Types of Screen Printing

There are three main types of screen printing: textile screen printing, graphic screen printing, and industrial screen printing. Each type of screen printing is used for different applications and produces different types of printed products.

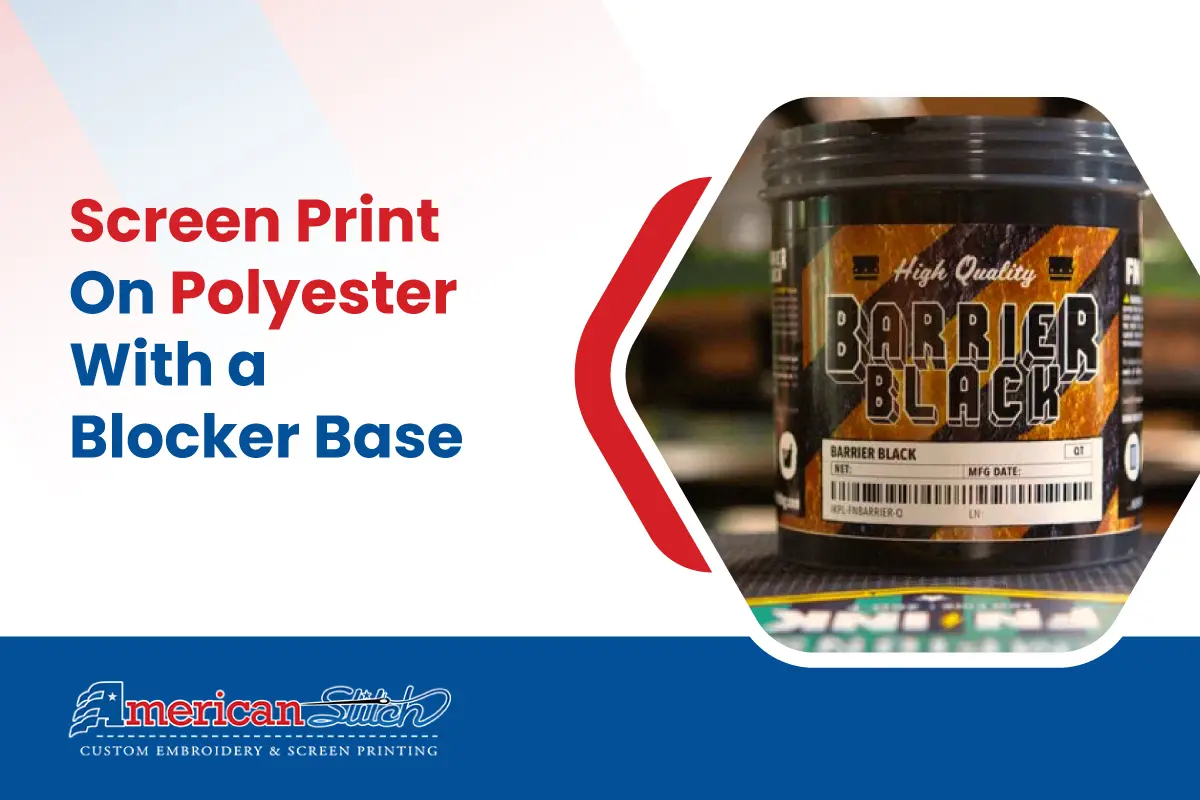

Textile Screen Printing

Textile screen printing is the most common type of screen printing, and it is used to print designs onto fabrics such as t-shirts, hoodies, and other apparel. Textile screen printing uses a specific type of ink that can adhere to fabric and withstand repeated washing without fading or cracking. The process involves creating a stencil of the design on a fine mesh screen, which is then used to apply the ink to the fabric.

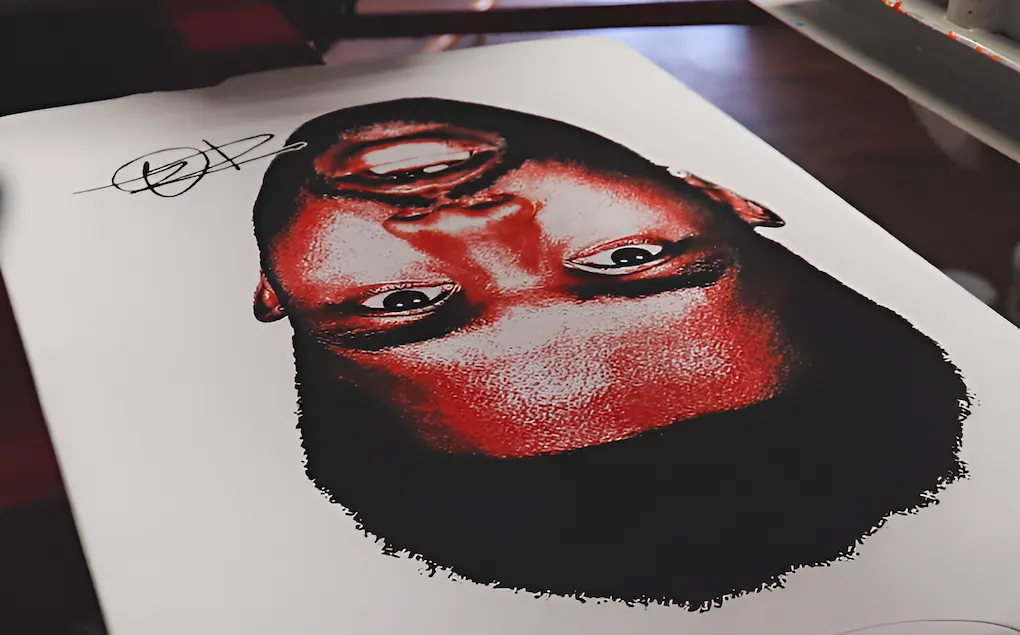

Graphic Screen Printing

Graphic screen printing is used to print designs onto non-fabric materials such as paper, vinyl, and plastic. This type of screen printing is commonly used for printing signs, banners, decals, and other graphic designs. The process is similar to textile screen printing, but the ink used is different and is designed to adhere to non-fabric materials.

Industrial Screen Printing

Industrial screen printing is used to print on a wide variety of materials including metals, plastics, glass, and ceramics. This type of screen printing is commonly used for products such as electronics, appliances, and automotive parts. Industrial screen printing requires specialized inks that can adhere to the specific material being printed on, and the process typically involves using automated machinery to ensure precise printing.

Overall, screen printing is a versatile printing method that can be used for a wide variety of applications and products. Each type of screen printing requires specialized equipment and techniques, and it’s important to choose the appropriate type of screen printing for your specific application.

Benefits of Screen Printing

Screen printing offers several benefits that make it a popular choice for printing on a wide range of materials. Here are some of the key benefits of screen printing:

Quality and Durability

Screen printing produces high-quality and durable prints that can withstand wear and tear over time. The ink used in screen printing is thick and opaque, which means that the colors remain vibrant and bright even after multiple washes or uses.

Cost-Effective

Screen printing is a cost-effective way to produce large quantities of printed materials, such as t-shirts or banners. Once the screens are set up, the printing process is relatively quick and straightforward, which reduces the overall cost of production.

Versatility

Screen printing can be used to print on a wide variety of materials, including fabrics, plastics, and metals. This versatility makes it a popular choice for printing on everything from clothing to signage to industrial products.

Customization

Screen printing allows for a high degree of customization, with the ability to print a wide range of colors and designs. This makes it a popular choice for creating personalized or unique items, such as custom t-shirts or promotional products.

Large Print Sizes

Screen printing is capable of producing large prints, which makes it ideal for creating large-format signage, banners, and other promotional materials.

Overall, screen printing offers a combination of quality, durability, versatility, and affordability that make it a popular choice for a wide range of printing applications.

Challenges of Screen Printing

While screen printing offers several benefits, there are also some challenges associated with this printing method. Here are some of the main challenges of screen printing:

Time-Consuming

Screen printing can be a time-consuming process, especially when multiple colors or designs are involved. Each color in the design requires a separate screen and printing process, which can add time and complexity to the overall process.

Limited Color Options

Screen printing uses a limited number of colors, which can make it challenging to produce complex or detailed designs. The number of colors used in a design is limited by the number of screens available and the complexity of the design.

Setup Costs

Setting up the screens and equipment for screen printing can be expensive, especially for small print runs. This can make screen printing less cost-effective for small businesses or individuals who need a limited number of prints.

Not Suitable for Small Details

Screen printing is not well-suited for printing small details or fine lines. This is because the ink used in screen printing is thick and can bleed, which can result in smudged or blurry details.

Environmental Impact

The screen printing process uses a significant amount of water, chemicals, and energy, which can have a negative impact on the environment. However, there are eco-friendly alternatives available that use water-based inks and sustainable printing processes.

Overall, while screen printing offers several benefits, there are also some challenges associated with this printing method. It’s important to weigh the pros and cons of screen printing before deciding if it’s the right choice for your printing needs.

How to Get Started with Screen Printing

Getting started with screen printing involves several steps, including acquiring the necessary equipment, preparing the screens and ink, and mastering the printing process. Here’s a general overview of the steps involved in getting started with screen printing:

Equipment Required for Screen Printing

To get started with screen printing, you’ll need a few key pieces of equipment, including a screen printing press, screens, squeegees, ink, and a source of light for exposing your screens. You’ll also need a workspace that’s large enough to accommodate your equipment and materials.

Difference Between Screen Printing and Digital Printing

Screen printing and digital printing are two different printing methods with some key differences. Here are some of the main differences between screen printing and digital printing:

| Screen Printing | Digital Printing | |

|---|---|---|

| Process | Screen printing involves the use of a stencil, called a screen, through which ink is pressed onto the material being printed. | On the other hand, involves the use of a digital image that is printed directly onto the material. |

| Color Options | Screen printing is limited to a fixed number of colors, usually up to 6 or 8 colors per design. | on the other hand, can produce a virtually unlimited number of colors and color gradients. |

| Print Quality | Screen printing is known for producing high-quality, durable prints that can last a long time. | Digital printing can produce high-quality prints as well, but the quality may not be as long-lasting as screen prints, especially if the printed item is washed or exposed to the elements. |

| Cost | The cost of screen printing varies depending on the number of colors used and the size of the print run. | Digital printing is often more cost effective for small print runs, but screen printing can be more cost effective for larger print runs. |

| Materials | Screen printing can be used on a wide range of materials, including fabric, paper, plastic, and metal. | Digital printing is more limited in terms of the materials it can be used on, and may not be suitable for certain materials. |

Overall, screen printing and digital printing are both effective printing methods with their own advantages and disadvantages. The choice between the two will depend on the specific printing needs of the project, such as the materials being used, the number of colors required, and the size of the print run.

Difference Between Silk Screen Printing and Heat Transfer

| Silk Screen Printing | Heat Transfer | |

|---|---|---|

| Process | Silk screen printing involves pressing ink through a stencil onto the fabric. | Heat transfer involves printing a design onto transfer paper and then using heat to transfer the design onto the fabric. |

| Print Quality | Silk screen printing is known for producing high-quality, durable prints that can last a long time, especially when the ink is properly cured. | Heat transfer can produce high-quality prints as well, but the print quality may not be as long-lasting as screen prints, especially if the transfer is not properly applied or the transfer paper is of poor quality. |

| Color Options | Silk screen printing can use a wider range of colors than heat transfer. Silk screen printing also offers the option of using special inks, such as metallic or glow-in-the-dark inks. | Heat transfer is often limited to a fixed number of colors. |

| Cost | The cost of silk screen printing can be more expensive than heat transfer, especially for smaller print runs. | Heat transfer can be a more cost-effective option for small runs, but for larger runs, silk screen printing may be more cost-effective. |

| Materials | Silk screen printing can be used on a wide range of fabrics, including cotton, polyester, and blends. | Heat transfer is generally suitable for cotton and polyester fabrics, but may not be suitable for other types of fabrics or materials. |

Applications of Screen Printing

Screen printing is a versatile printing method that can be used for a wide range of applications. Here are some of the most common applications of screen printing:

Apparel: Screen printing is commonly used to print designs on apparel, such as t-shirts, hoodies, and hats. The durable and high-quality prints produced by screen printing make it a popular choice for apparel brands.

Promotional Items: Screen printing is also commonly used to print designs on promotional items, such as tote bags, water bottles, and pens. These items are often given away as promotional gifts or sold as merchandise.

Signage and Banners: Screen printing is well-suited for producing large-scale prints, making it a popular choice for signage and banners. The durable and weather-resistant nature of screen printing also makes it a good option for outdoor applications.

Decals and Stickers: Screen printing is commonly used to produce decals and stickers for a wide range of applications, including branding, labeling, and decoration.

Packaging: Screen printing can be used to print designs directly onto packaging materials, such as boxes and bags. This can be an effective way to create branded packaging that stands out on store shelves.

Fine Art: Screen printing can also be used to produce fine art prints, such as limited edition prints and posters. The versatility of screen printing allows artists to create unique and complex designs that would be difficult or impossible to produce with other printing methods.

Overall, screen printing is a versatile and popular printing method that can be used for a wide range of applications. Its ability to produce high-quality and durable prints makes it a popular choice for many businesses and individuals.

Conclusion

In conclusion, screen printing is a versatile printing technique that has been around for centuries and continues to be used in various industries today. It offers high-quality and durable prints, making it a popular choice for apparel, promotional products, signage, and more.

While it does have some challenges, such as limited color options and being time-consuming, the benefits of screen printing outweigh the drawbacks for many businesses and individuals. With the right equipment and knowledge, anyone can learn how to master the art of screen printing and create high-quality prints that will last for years to come.

We’re Here to Help

No matter your printing needs or where you are in the process, we’re here to assist you. Contact us at (918) 508-3634 for immediate solutions to your screen printing requirements. Unlock the full potential of this versatile printing method and bring your creative visions to life with the vivid colors and durability of screen printing.